Air and dirt issues

The performance of wet-heating and chilled-water systems can be seriously compromised by air in the system and the resulting corrosion. Ken Sharpe finds out how Spirotech tackles the problem.

|

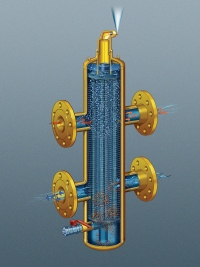

| Both air and dirt can be removed from a system using this single unit. |

Dr Daphne Scholten of Spirotech at Helmond in The Netherlands has a neat little party trick to show the effectiveness of the company’s technology at removing air from water in pipework systems.

She carefully pours some fizzy water into a small glass tumbler — carefully, so as not to disturb the dissolved carbon dioxide.

She then equally carefully lowers into the tumbler a Spirotech element that is normally concealed inside the distinctive yellow metal casing of the company’s products. The glass tumbler is conveniently cylindrical so that the Spirotech element fits snugly.

What happens next is a massive turbulence of carbon dioxide coming out of solution in a huge froth of bubbles caused by the nucleating effect of the large area of rough surface presented by the fine copper wire that makes up a Spirotech element.

It’s tempting to try the same trick with Champagne, but the glass has to be cylindrical — which is the wrong shape for Champagne to be enjoyed properly. And in any case, you would probably be warned not to drink the Champagne afterwards.

Air dissolved in water, hot or cold, in a pipework system is unlikely to be present in the same large quantities as carbon dioxide in carbonated water, but it nevertheless presents numerous undesirable problems.

Not that the presence of air in a system is necessarily recognised as a problem, However, dirt in a system is — and it is the oxygen in air in a system, that leads to the corrosion that becomes the dirt and debris, including the dreaded magnetite.

Preventing air entering a piped-services system is the ideal approach. However, there are various ways that air can get into a system — so there is a need to remove it.

In traditional heating and cooling systems, such dirt was not too much of a problem. However, as marketing manager Mark von den Hoff explains, the measures taken to continually improve energy efficiency make modern systems fare more susceptible to the adverse effects of debris. Not only does performance suffer, but so does reliability and, in extreme cases, longevity. Even something as small and seemingly innocuous as a micro-bubble can block a small waterway in, for example, a heat-exchange coil. ‘Unless we can get the water quality right,’ says Mark von den Hoff, ‘the system will fail.’

Von den Hoff says that he has never seen a system more than a year old without corrosion.

Potential problems include cold spots in the radiators of heating systems caused by air or dirt. It may be that air is not the problem but the evolution of gases such as hydrogen, methane and ammonia as by-products of corrosion.

Bacteria can also grow in a system, especially in the lower temperatures at which modern heating systems operate.

A freshly filled system using local tap water will contain about 10% dissolved gases, which are, of course, less soluble in warm and hot water. Even after that air has been removed, make-up water will bring more air into a system.

Plastic pipework is even more susceptible to air getting into the system as the plastic of many pipes is permeable to air. The solution is to install plastic pipes that have an oxygen barrier.

An expansion vessel that is too small will also lead to problems. Water will be lost as the pressure-relief valve opens — only to be replaced with fresh water containing more air.

Given that you can’t keep air out of a system, the need is to remove it, and the corrosion debris that forms.

Spirotech has specialised in removing air and debris from such systems for over 35 years. Indeed, the company has a research and development department at Helmond dedicated to just those tasks, and its products are marketed all over the world.

|

The company has long had a presence in the UK and set up a UK office in 2004. Earlier this year, a new UK head office was opened at Solihull.

One of Spirotech’s team in the UK is commercial manager Martin Wilkinson. He explains that while the Spirotech system is one of the most efficient at removing air, where it is installed in a pipework system is very important.

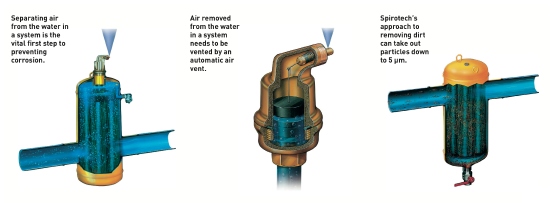

Because air is more soluble at cooler temperatures, the best place to put an air separator is at the hottest point in a system. In a heating system, the best point is just after the boiler. In a chilled-water installation, the air separator is best placed in the return and just before the chiller.

The design of the unit has a very low pressure drop so as not to add significantly to the pump loading.

As the various illustrations demonstrate, the Spirotech unit is very effective at separating air from the entire volume of water in it. Equally important is ensuring that the separated air is actually vented from the unit — unlike troublesome installations that have been investigated by the company’s technicians.

Martin Wilkinson explains, ‘The automatic air vent is the key to the whole system. Our air vents are hand assembled in a special room. It is not a clean room as such, but it is separate from the main part of the factory.’

Design features of the automatic air vent include a solid float that cannot rupture and a sliding connection between the valve and float to prevent hunting. The inside of the vent is highly polished to avoid dirt adhering to it and potentially causing the float to stick.

Given that air in a system and, hence, corrosion are inevitable, Spirotech has also evolved its technology to separate and remove dirt particles. The approach can remove dirt particles down to 5 µm — avoiding problems with sensitive systems. A convenient feature is being able to remove the separated dirt from a unit while the system is in operation.

And for completeness, why not combine the functions of air and dirt separation into a single unit. Capital and installation costs will both be reduced. However, thought will need to be given to how such a unit is installed so that air is separated from the hottest part of the circuit (flow off a boiler or return to a chiller) and dirt from the coolest part (return to a boiler or flow from a chiller).

It is never too soon to remove air from a system, explains Mark von den Hoff — adding that the longer air is allowed to stay in a system, the more problems will occur.

Indeed, there is a real case for removing air even before commissioning work begins. To illustrate the point, Mark von den Hoff refers to the heating system of an office block with numerous rooms. Like many other such installations, the many runs of horizontally staggered pipes made the system difficult to vent, so a SpiroVent Superior vacuum degassing unit was installed.

These units remove dissolved air by taking a quantity of liquid from the flow and subjecting it to a reduced pressure. Dissolved air comes out of solution, and the liquid is returned to the main system. For this particular project, over 1000 l of air was removed from the system, enabling it to be commissions extremely quickly.

Mark von den Hoff explains, ‘Normally the commissioning of a complicated system is made difficult by the air in the system.’

Spirotech has over 35 years of experience and a fully equipped research-and-development department dedicated to air and dirt separation. While the physical laws have remained the same, the products themselves continue to evolve. In addition, the need for such products to prevent the problems caused by corrosion and debris and maintain the efficiency of plant and systems grows in importance. Such contamination will quickly compromise the efficiency of a system, which is very much against the objective of using energy more efficiently.