Modulating boilers are ideal partners for underfloor heating

Modern condensing boilers have a wide modulation range, making them well suited to use with underfloor heating. This particular boiler has two pairs of tappings, with one pair delivering a higher temperature for domestic hot water.

DAVID WHITFIELD explains how the built-in modulation and control capabilities of modern condensing boilers should be utilised to achieve more efficient underfloor heating systems.The wide modulation range of modern burners makes underfloor heating (UFH) the ideal partner for condensing boiler technology. For example small boilers in our Geminox range have a wide linear modulation range from 0.9 up to 9.9 kW and from 2 to 17 kW. UFH is by far the best matched heating solution for condensing-boiler technology, enabling the wide modulation and low down turn of premix burners to be exploited for maximum efficiency.

Differences of opinion Are the design principles for UFH complicated — or has the UK market been confused by many differences of opinion from some sections of our industry that do not want to change and from UFH manufacturers who provide over-elaborate controls and do not understand the European principle of a wide temperature difference (Delta T) of 20 K between flow and return temperatures being incorporated into the design like our European partners? With some UFH manufacturers still unsure about direct burner modulation and advising clients that ‘their’ way is the only solution, the market place can be confusing for the client, who is presented with many different views on what control package is really required and how best to control the UFH temperature. Why do some UFH suppliers insist that the only way to control UFH is using an area pack consisting of a mixing valve and a high-head pump using a Delta T of 5 K? This principle was OK in the early 1980s when we only had on/off boilers. It makes no sense today to leave the boiler at high temperature and then reduce it down to a pre-set UFH temperature to run at 55°C all through the heating season. On mild winter days the UFH can perform with temperatures as low as 30°C or less, ensuring that the condensing boiler is running at its peak efficiency and that the floor has an even temperature and provides mild heat with maximum comfort. Our boilers, for example, have built-in microprocessor-controlled burner modulation, so the UFH installation cost can be reduced dramatically. Temperature-reducing equipment is not required, as the flow temperature can be set to the requirement of the UFH manufacturer. As well as reducing costs, this approach makes life easier for all parties as the boiler can be piped directly to the UFH manifold.

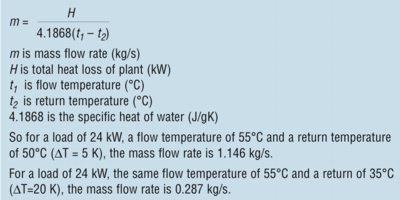

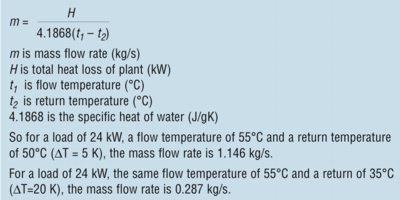

Calculation The calculation below shows that using a Delta T of 20 K on a condensing boiler, the size of pipework and pump can be reduced to suit the smaller mass flow. The reduction in installation costs by using smaller pipework and pumps can be significant on some projects. As well as lower material costs there will also be savings in labour costs.

The reduction in pipe and pump size is due to a greater difference between flow and return temperatures (see panel). The ideal temperatures with a condensing boiler and UFH are a maximum flow of 55°C and a return of 35°C or 60/40°C for an outside air temperature of –3°C. This will achieve our low return temperature target of below 55°C, but this also results in a smaller mass flow being required, which enables pipe and pump sizes to be reduced. Using design criteria of 55/50°C provides a mean temperature of 52.5°C. Using 60/40°C still provides a mean temperature of 50°C and using 55/35°C a mean temperature of 45°C. This mean temperature is simply used in the UFH design when calculating pipework and heating layouts. A modulation effect should be applied to the UFH pipework layout in a similar way to the burner of a condensing boiler modulating its output to match the heating needs. At Multibeton (which manufactures, designs and installs underfloor heating systems), modulation of the UFH output is achieved by increasing pipework at the outside walls and areas of high glazing, where there is a higher demand for heat, and easing off the heating output near internal walls with lower heat demand by using less pipework in these areas. This principle will ensure that even, comfortable heat is applied to the entire room and that there will be no hot spots. Using standard pipe centres throughout the room can result in cold spots at the outside walls and higher temperatures near the internal walls.

Modulation The modulation approach used by Multibeton makes using a Delta T of 20 K an ideal solution for UFH. The modulation design has been used successfully for over 30 years in many countries across Europe, some with harsher climatic conditions than the UK. Good UFH design will ensure that there is adequate pipe to operate at the lowest possible water temperature. This reduces the surface temperature and gives an even, comfortable surface temperature over the entire floor. Systems that use standard centres in every room often have to run at a higher temperature to overcome the poor design, and this in turn results in uneven temperatures, uncomfortable conditions and floor hot spots. Direct burner modulation via compensation will ensure that the property only receives the amount of heat it requires at any one time of the heating season. Using the principle that the initial design would have been to maintain the room temperature at 21°C with an outside temperature of –3°C and that this design parameter is not required for all the UK heating season, the UFH circuit pipework and floor construction will work exactly the same as any other heat emitter in varying its output to match the needs of the room in varying climatic conditions. If the UFH design requires 8 kW at –3°C outdoors, it may be required to supply only about 3 kW when the outside air is at 12°C. This can be achieved by lowering the flow temperature from the boiler rather than still supplying 55°C throughout the entire heating season, which is a waste of energy and encourages boiler cycling. You do not need to supply water at 55°C and provide 8 kW all heating season when, for the vast majority of the heating season, less heat will be required. Direct burner modulation via compensation and modulation of the UFH output due to the pipework layout design will enable a condensing boiler and UFH to provide maximum efficiency and maximum comfort conditions.

David Whitfield is managing director of Geminox-UK, Unit B Blenheim House, 1 Blenheim Road, Epsom, Surrey KT19 9AP. Additional information was provided by Bill Emmerson, managing director of Multibeton Ltd, 15 Oban Court, Hurricane Way, Wickford Business Park, Wickford, Essex SS11 8YB.

Related links: