Towards energy-efficient ductwork

Energy-efficient ductwork —Kingspan KoolDuct pre-insulated ductwork can save over 30% of the energy required to run a fan in an HVAC system, and thus its carbon-dioxide emissions. It can also reduce the risk of a system failing to comply with any pressure testing that is required by the new Approved Documents L2 of the Building Regulations.

JOHN GARBUTT highlights energy-efficiency issue for ductwork in the latest Building Regulations.One of the most profound impacts of climate change is the increased demand for air-conditioning to maintain comfortable temperatures in buildings. Since air-conditioning is a notoriously big consumer of energy this will exacerbate the problem of carbon dioxide emissions, so the vicious global warming circle is perpetuated. However, the latest changes to the Building Regulations have taken steps to tackle the issue. Apart from steps to limit the effects of passive solar gain, the energy efficiency of air-conditioning systems and their distribution ductwork is now under close scrutiny.

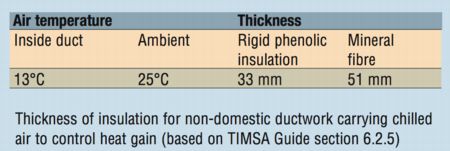

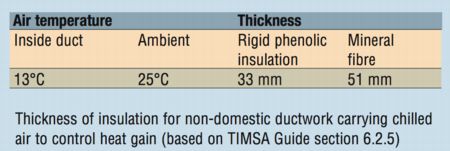

Ductwork performance The new Approved Documents L2A and 2B look at ductwork performance in three different ways. The first issue tackled by the new approved documents is the savings in energy consumption and carbon-dioxide emissions savings to be made from a change in insulation standards for ductwork. The approved documents refer directly and indirectly to the new ‘TIMSA guide to achieving compliance with Part L of the Building Regulations for domestic and non-domestic heating, cooling and ventilation’* This guide provides a single point of reference for all duct and pipework insulation thicknesses. The table below shows the thicknesses of insulation that the TIMSA Guide and, hence, the approved documents require for ductwork carrying chilled air. However, insulation is only one aspect of improving the energy performance of ductwork. Air-tightness also has a significant effect on the overall energy efficiency and carbon-dioxide emissions associated with a ductwork system, which is taken into account by the second and third appearances of ductwork in the requirements.

Emissions calculation The calculation of the overall carbon-dioxide emissions of the building is the main unavoidable feature of the Approved Document L2A and appears as an option in ADL2B. The rub (and the second appearance) is that one factor included in the calculation is that of ductwork air-leakage. Lower air leakage will reduce the carbon-dioxide emissions of the building and, therefore, help it comply with the requirements of the approved documents.

The third appearance relates to limiting air leakage. The design standards set out in ADL2A state that ventilation ductwork should be made and assembled in accordance with the specifications given in HVCA DW/144 and tested in accordance with HVCA DW/143 on systems served by fans with a design flow rate greater than 1 m3/s and for those sections of ductwork where the pressure class is such that DW/143 recommends testing and the carbon dioxide emissions rate of the building design assumes a leakage rate for a given section of ductwork that is lower than the standard defined in DW/144 for its particular pressure class.

Remedial work Further, Approved Document L2A states that if a ductwork system fails to meet the leakage standard, remedial work should be carried out to achieve satisfactory performance in re-tests, and further ductwork sections should be tested as set out in DW/143. It is clearly vital to reduce the risk of ductwork failing to achieve the designed air-leakage to avoid project delays and penalties. It is equally important to know what air-leakage can be assumed for calculating the carbon-dioxide emissions of the building. Pre-insulated ductwork is generally assumed to be more airtight than the galvanised steel alternative and therefore at less risk of failure. However, exactly how airtight it is and what benefits might accrue from that needed to be quantified. Kingspan Insulation commissioned an independent study by the Building Services Research & Information Association (BSRIA) to examine the air-leakage of traditional galvanised-sheet-steel ductwork and pre-insulated ductwork systems and ascertain how much difference air tightness can make. The test examined 100 m runs of ductwork with internal dimensions of 600 x 600 mm. The results for pre-insulated ductwork show a reduction in air leakage and, consequently, flow rate of 11.6%, saving 31% of the energy required to run a fan in an HVAC system with a typical design flow rate of 7.5 m/s and also giving a 31% reduction in carbon-dioxide emissions. At lower flow rates, there are potentially even greater savings to be made. Further work by Bucknall Austin concluded that for a 100 m run of ductwork, with internal dimensions of 600 x 600 mm and an air velocity of 7.5 m/s, the pre-insulated ductwork could save 3100 kWh per annum, equating to a saving of 1.3 t of carbon dioxide per year compared with galvanised sheet steel.

Lower the risk In conclusion, pre-insulated ductwork can lower the risk of HVAC ductwork failing to comply with the requirements for air-leakage testing of the new ADL2A and ADL2B. It can also save over 30% of the energy required to run a fan in an HVAC system and, hence, reduce the carbon dioxide emissions of the system. The KoolDuct System of pre-insulated ducting is lightweight, takes up less space and can be installed up to three times faster than sheet-metal ducting — not including the further time taken to lag the latter. KoolDuct will soon be available in a 33 mm thickness to suit the demands of the TIMSA Guide. Kingspan Insulation has produced a booklet ‘Overeating resources?’, which outlines the findings of the BSRIA and the Bucknall Austin reports. Telephone 0870 733 8333 to request a copy.

John Garbutt is marketing director with Kingspan Insulation Ltd, Pembridge, Leominster, Herefordshire HR6 9LA.

Related links: